BHS-Sonthofen GmbH

Booth number: E92

www.bhs-sonthofen.com/

About us

BHS-Sonthofen is an owner-operated group of companies specializing in machinery and plant engineering with headquarters in Sonthofen, Germany. In keeping with our mission "Transforming Materials into Value," we offer innovative process solutions, technologies and consulting services in the business areas Process Technology, Building Material Machinery, as well as Recycling Technology. Our experts in the field of mechanical and thermal process technology with a focus on filtration, drying, mixing, crushing, and recycling form the basis for our success.

Address

An der Eisenschmelze 47

87527 Sonthofen

Germany

E-mail: info@bhs-sonthofen.com

Phone: +49 8321 60990

Internet: www.bhs-sonthofen.com/

6-3-252/1/7/B, 3rd floor, Erramanzil, Prakash Lights Building, Banjara Hills

500 034 Hyderabad

India

E-mail: info@bhs-sonthofen.in

Phone: +91 40 2331 53-41 / -45 / -46

Internet: www.bhs-sonthofen.com/

Contact person:

Sales Manager Nachiket Ranade

E-mail: nachiket.ranade@bhs-sonthofen.in

Phone: +91 781 5948353

Products & Services

The product range of BHS-Sonthofen for the building materials industry and mining industry contains following machines:

MIXING TECHNOLOGY: Twin-shaft batch mixer (Type DKX); Twin-shaft batch mixer (Type OX); Planetary mixer (BPX); Dry powder batch mixer (Type DMX); Twin-shaft continuous mixer (Type LFK); Single-shaft continuous mixer (Type MFKG); Laboratory mixer; Retrofitting for mixing plants

CRUSHING TECHNOLOGY: Rotor centrifugal crusher (RSMX); Rotor centrifugal crusher (RSMX); Rotor centrifugal crusher (RSMX)

Twin-Shaft Batch Mixer (DKX)

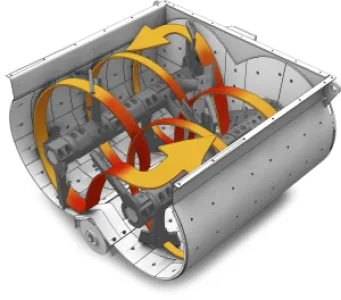

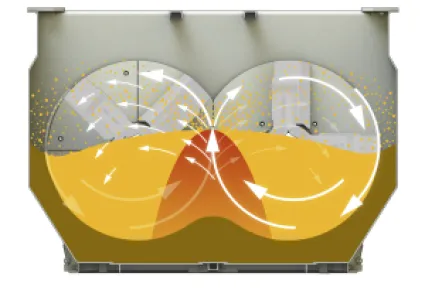

The twin-shaft batch mixer of type DKX from BHS-Sonthofen is the benchmark in concrete mixing technology. Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing technique has a significant effect on the quality of the mixture and the economic efficiency of the production process. Thanks to the proven design and arrangement of the mixing tools, you will achieve consistent homogeneous mixtures batch after batch in less time.

Twin-Shaft Batch Mixer (OX)

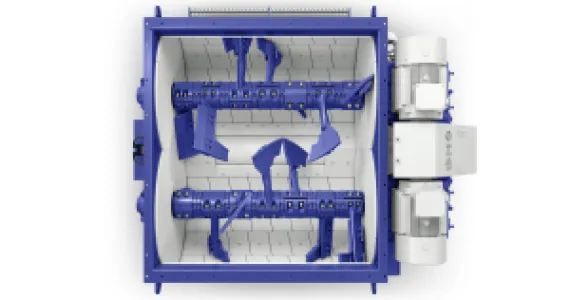

The twin-shaft batch mixer of type OX has been developed especially for this purpose as a standardized series machine to produce ready-mixed concrete in a cost-effective manner. Over 130 years of experience from BHS in mixing concrete is underlined in the technical details, which make quite a difference in practice – in the quality of the mixing result, in the high operating speed, and predominantly in the ability to reliably withstand the demands of the production of ready-mixed concrete in 24 /7 operation.

Twin-shaft continuous mixer (LFK)

The twin-shaft continuous mixer of type LFK is an efficient, reliable solution for continuous mixing processes, especially when handling coarser particles. The mixer is particularly suitable for the production of mineral mixtures, hydraulically-bound base layer concrete, landfill sealings, lean concrete, heavy concrete, dry mixtures etc. BHS also offers complete continuous mixing plants including sophisticated weighing, dosing and control technology as well as individual plant components.

Rotor impact mill (RPM)

The rotor impact mill is a high-performance crusher with a vertical shaft. The rotor impact mill enables you to achieve a high reduction ratio and excellent particle shape. The mill is suitable for crushing all low to moderately abrasive minerals and is therefore used predominantly in the production of sand for the concrete, asphalt and dry mortar industries.

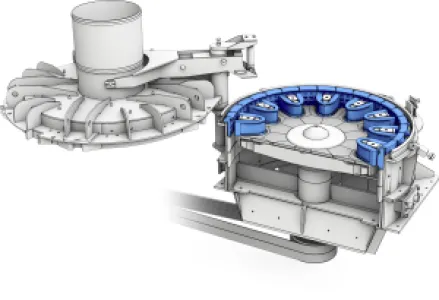

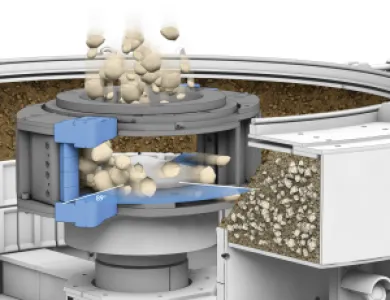

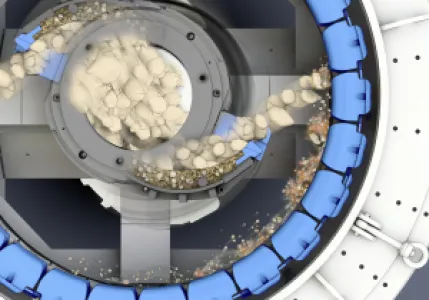

Rotor centrifugal crusher (RSMX)

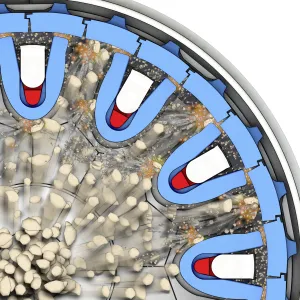

The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materials. It is suitable for all types of mineral materials, including highly abrasive feed materials and feed materials with a high hardness. Depending on its size, high throughput rates of 30 to 400 t/h can be achieved.

Every single particle of the input material undergoes extreme acceleration due to the centrifugal force in the rotor and is hurled against the impact wall. The impact wall can either consist of an anvil ring or alternatively of a material bed. Clogging is avoided due to the generous dimensioning of the rotor and housing. The crushing results can be substantially controlled and optimized by selecting a suitable speed.